The RMS-

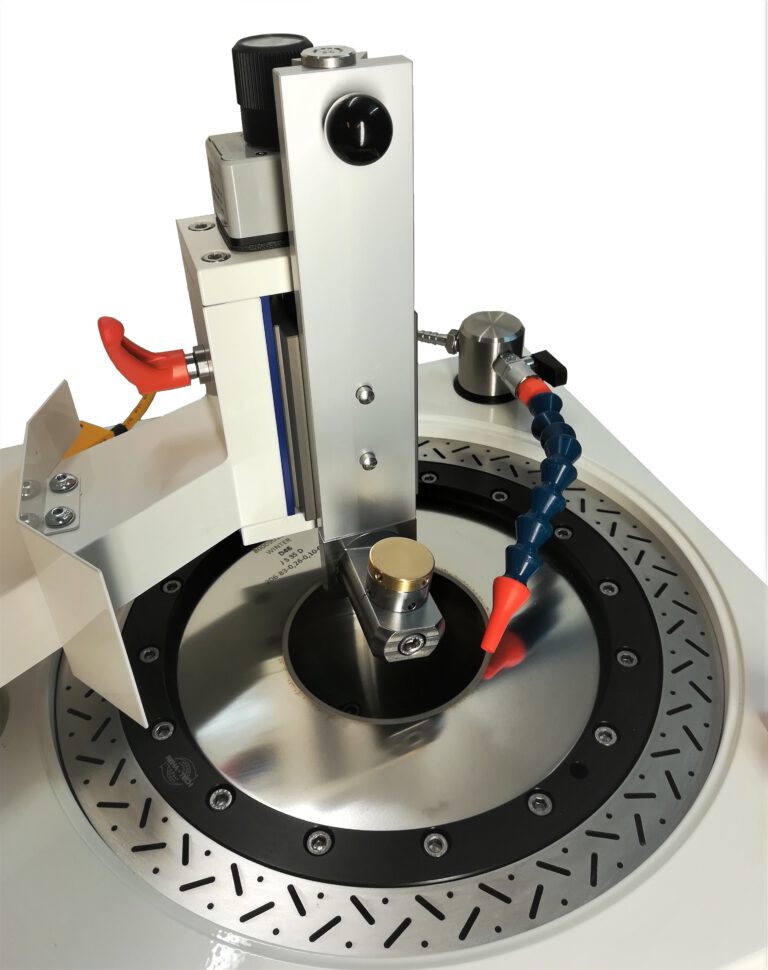

There is little waste of the specimen. Usually multiple serial sections can be made from one single tissue specimen. The speed of the object holder can be adjusted according to the specimen conditions. The cutting pressure is constantly monitored during the process by a built-in force-sensor©. If this becomes too large, the speed will be adjusted automatically and you can find this actual value on the display. Compared to the sectioning principle, the sawing method causes less compression. The speed of the rotating blade is approximately 600 rpm. During the sawing process, a constant flow of cooling agent is adjusted to land directly on the edge of the saw blade, and prevents overheating.

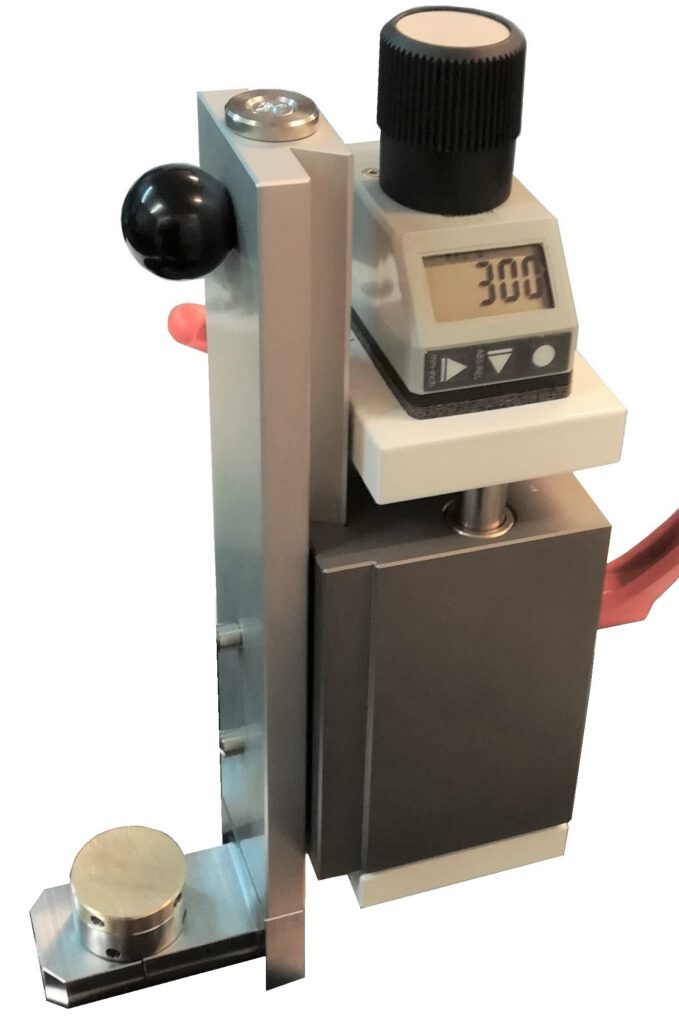

The digital counter makes it easy to adjust the thickness of the sample with a accuracy of 1 µm.